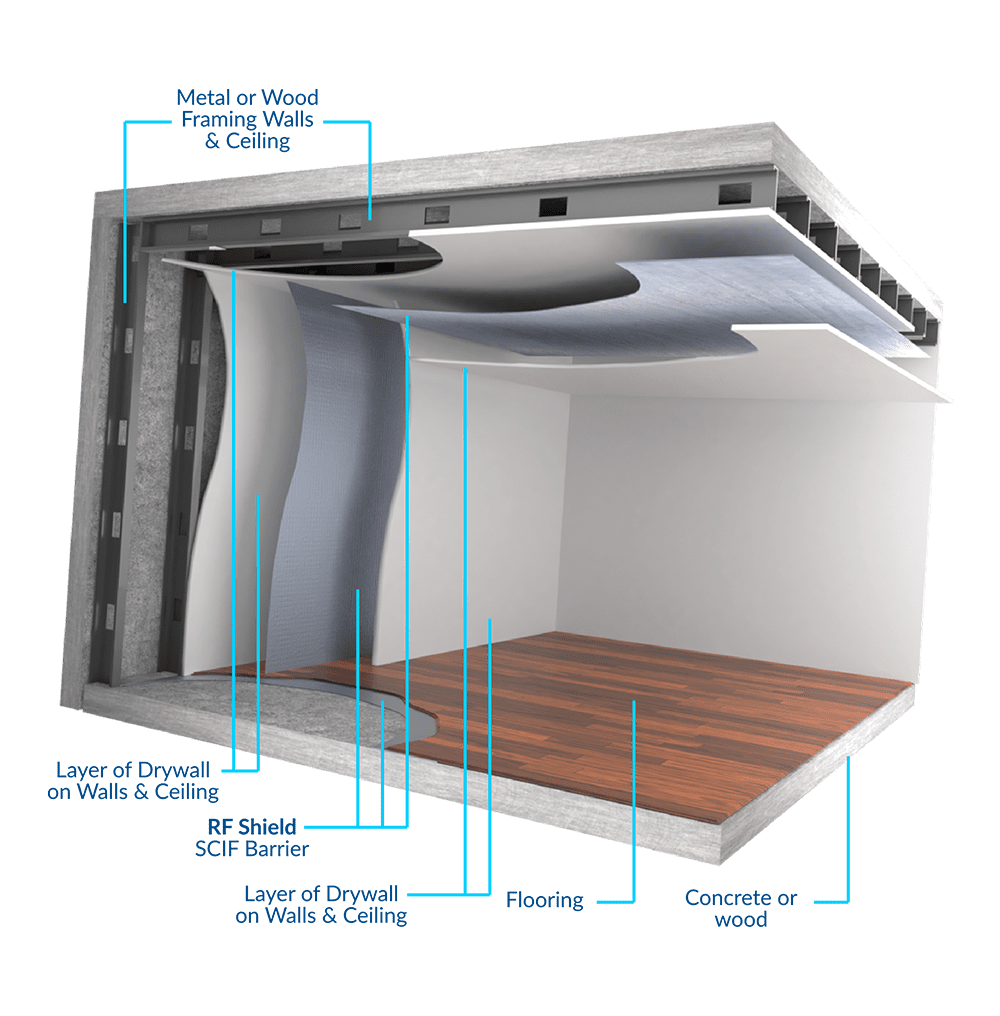

Surface Solutions provides end-to-end SCIF support—from early design and specification through construction, RF shielding, flooring, acoustic performance, testing, and remediation. Our work is guided by ICD/ICS 705 and current SCIF technical expectations.

4' × 4' galvanized steel shielding panels mechanically fastened and sealed at all seams with conductive foil tape. Surface Solutions does not install foil on floors—only rigid metal shielding systems are used.

Continuous silver RF shielding installed on wall assemblies with overlapped seams sealed using conductive foil tape to maintain electromagnetic continuity in accordance with ICD/ICS-705 requirements.

Silver RF shielding applied across ceiling surfaces with all joints taped and bonded to complete the secure RF envelope of the SCIF.

Executing the critical layers of a SCIF build—from shielding and structural continuity to inspection-ready installation.

Galvanized steel is steel coated with a protective zinc layer that prevents rust and corrosion. This coating enhances durability and ensures long-term performance even in harsh environmental conditions, making it a reliable material for secure and industrial construction projects.

Key Advantages:

We collaborate with architects, security officers, CTTA stakeholders, and general contractors to design SCIF assemblies that:

Typical deliverables:

Our field teams execute the critical layers that turn a shell or existing room into a SCIF-ready space:

SCIFs are inspected and documented throughout the build. We build with that process in mind.

In partnership with R.A. Mayes, we deliver RF shielding systems designed to manage electromagnetic emanations and meet specified attenuation targets.

Typical solutions include:

We coordinate closely with CTTA and security engineering stakeholders to ensure what’s on paper is what’s installed.

Moisture failures are a common—and expensive cause of downtime in secure facilities. Through our partnership with UZIN, we design and install flooring systems that may include:

When installed and documented per manufacturer instructions, systems can be supported by manufacturer warranty giving owners and accrediting stakeholders confidence in long-term performance.

We help design and install assemblies that achieve Sound Transmission Class (STC) targets required for secure facilities:

We support accreditation readiness by:

Our goal: no surprises at final inspection.

We’re often called when:

Remediation services include:

Whenever possible, remediation is designed to minimize disruption to ongoing operations.